AFW works with factories all over the world to bring our customers the best products at the best prices, ranging from unique ceramic accents from Mexico and quality canvas giclée artwork produced in Longmont, Colorado to quality leather furniture produced by Soft Line in Italy.

Soft Line has been designing and manufacturing high-quality Italian leather furniture for over 25 years. The company is based in Arzignano, Italy, a small town near Venice that is famous for its world-renowned leather district. This location allows Soft Line to purchase raw hides in Brazil and then leverage the expertise and attention to detail of the specialists in the district to transform the hides into the beautiful leather they use in their products.

Here’s a behind-the-scenes look at how Soft Line created the stylish and comfortable Barcelona All Leather Sofa from design to finished product.

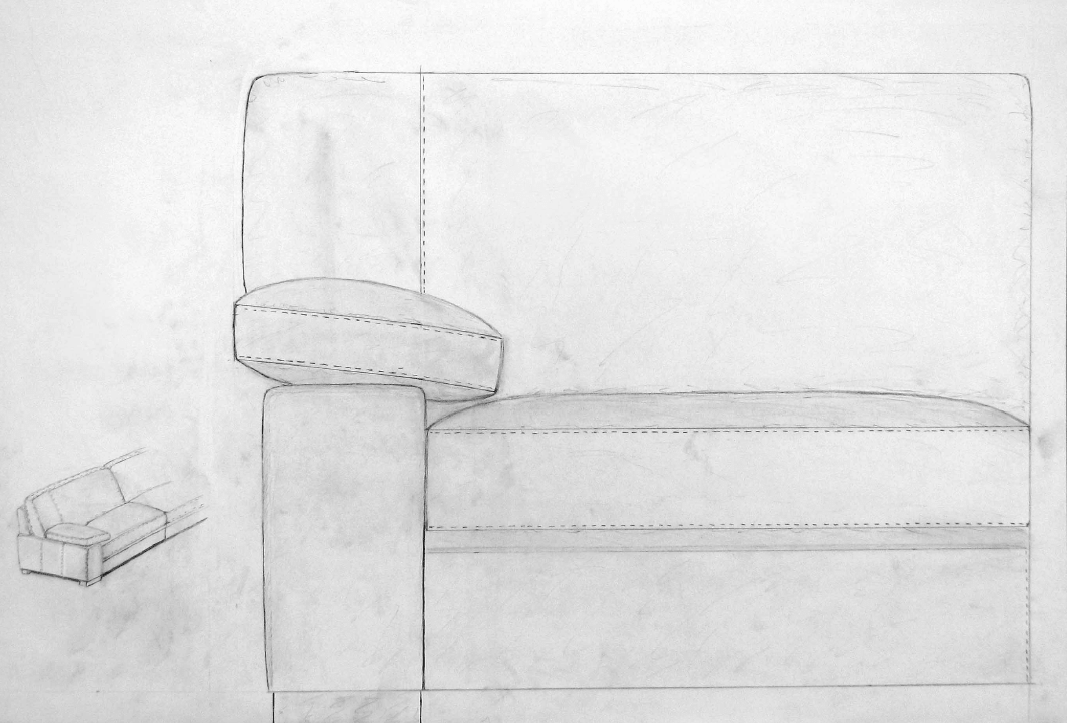

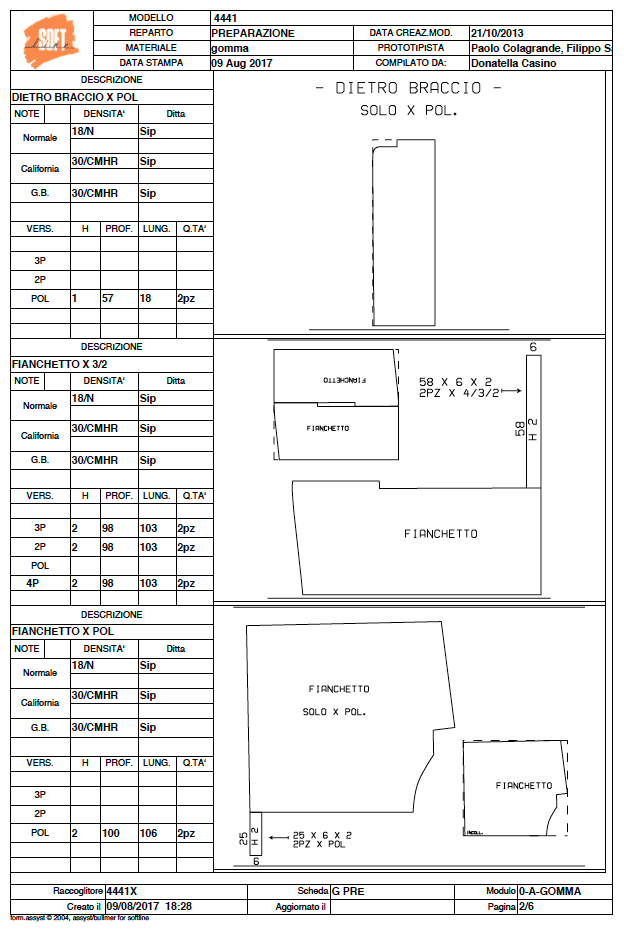

Soft Line’s head designer created the look of the Barcelona sofa by first drafting the design in pencil and then creating patterns for the wood frame, foam, and leather that will make up the sofa. The patterns are then entered into a computer-aided design (CAD) system.

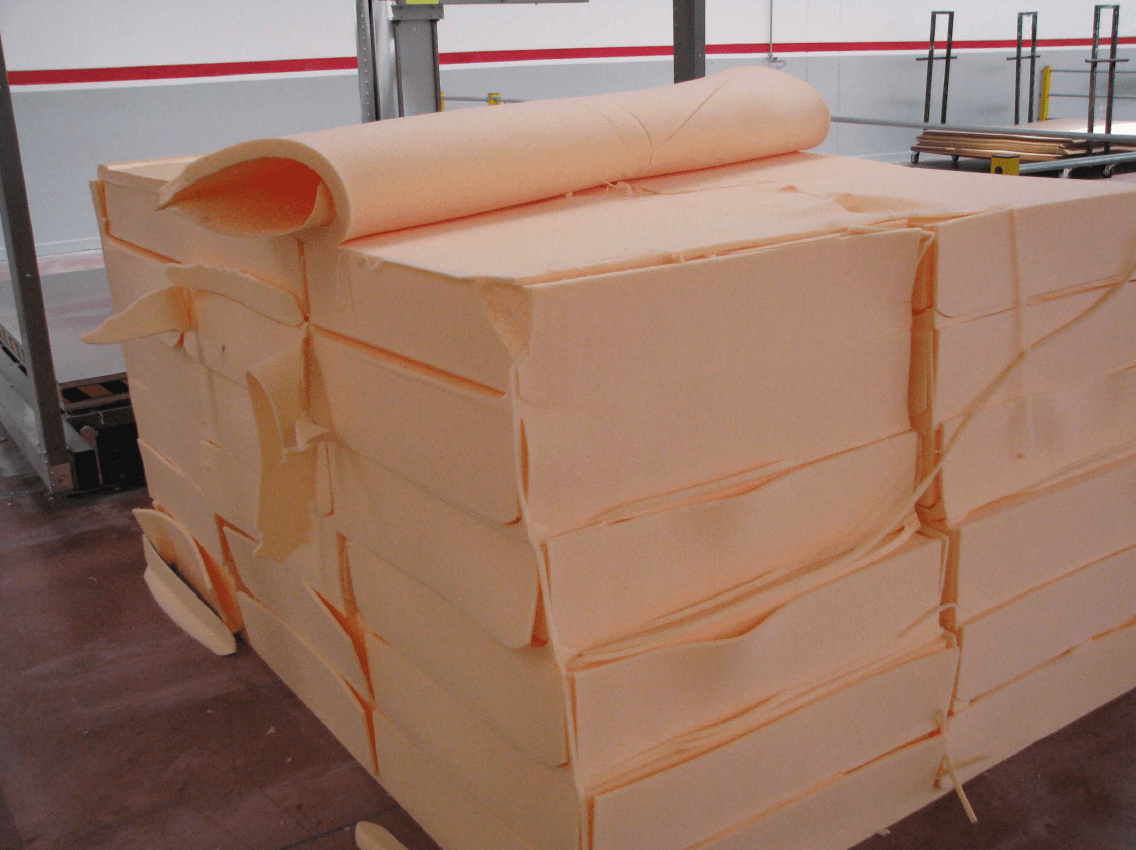

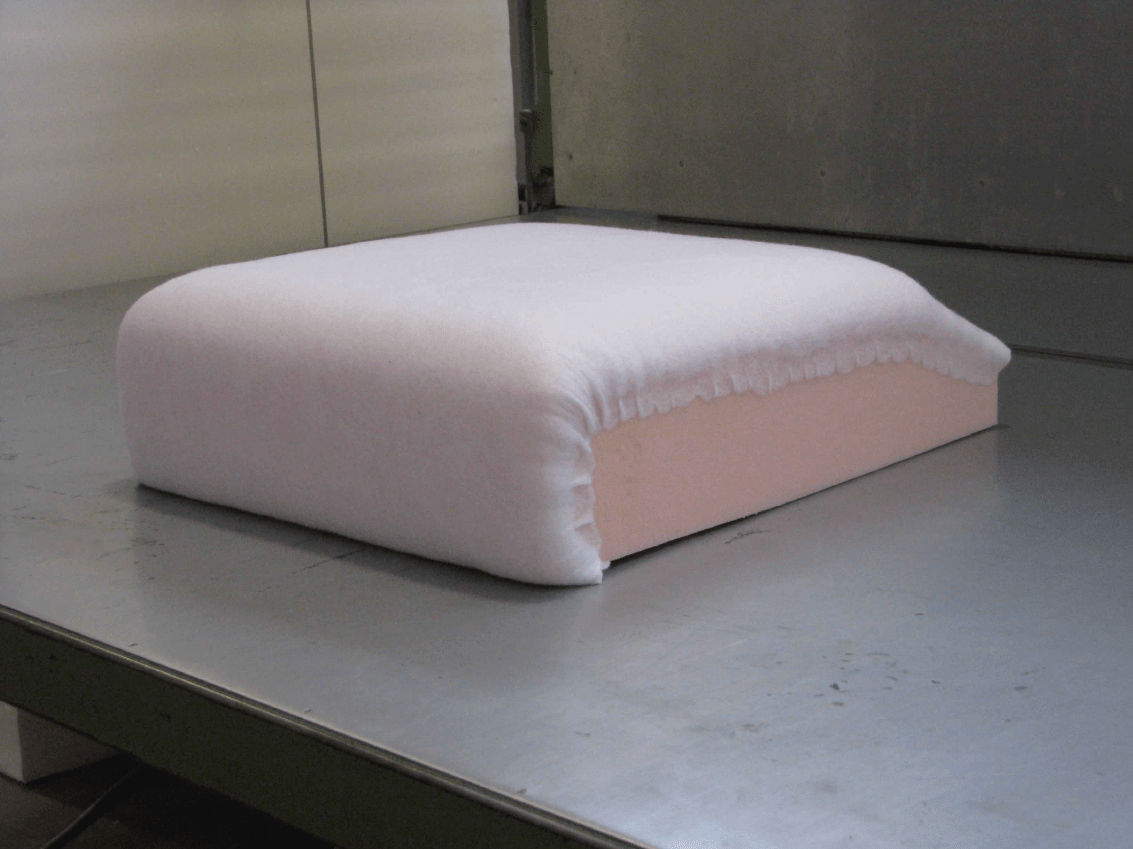

After the design is created, wood and foam are cut into pieces that will be assembled into the final product. In this step, the foam is cut using electronic machines to ensure consistency and then the foam for the seat cushions is carefully glued and wrapped in Dacron fiber for a smooth look.

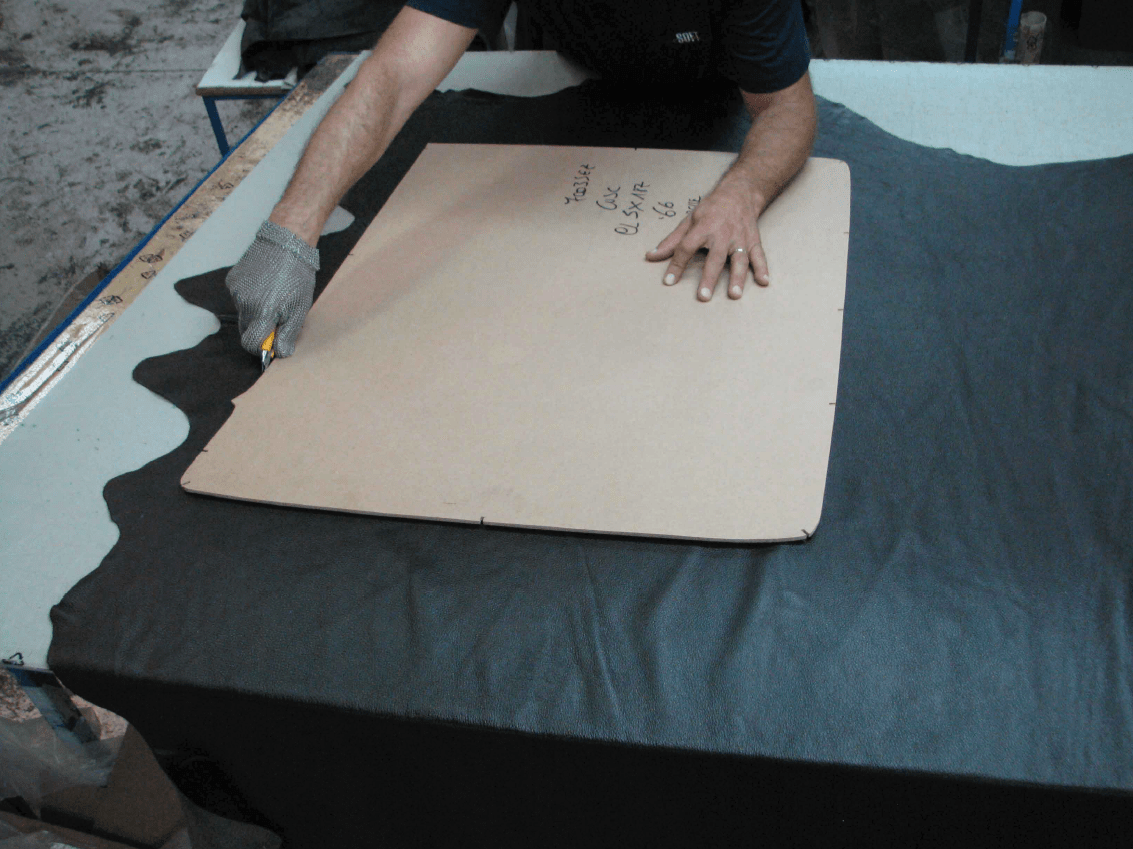

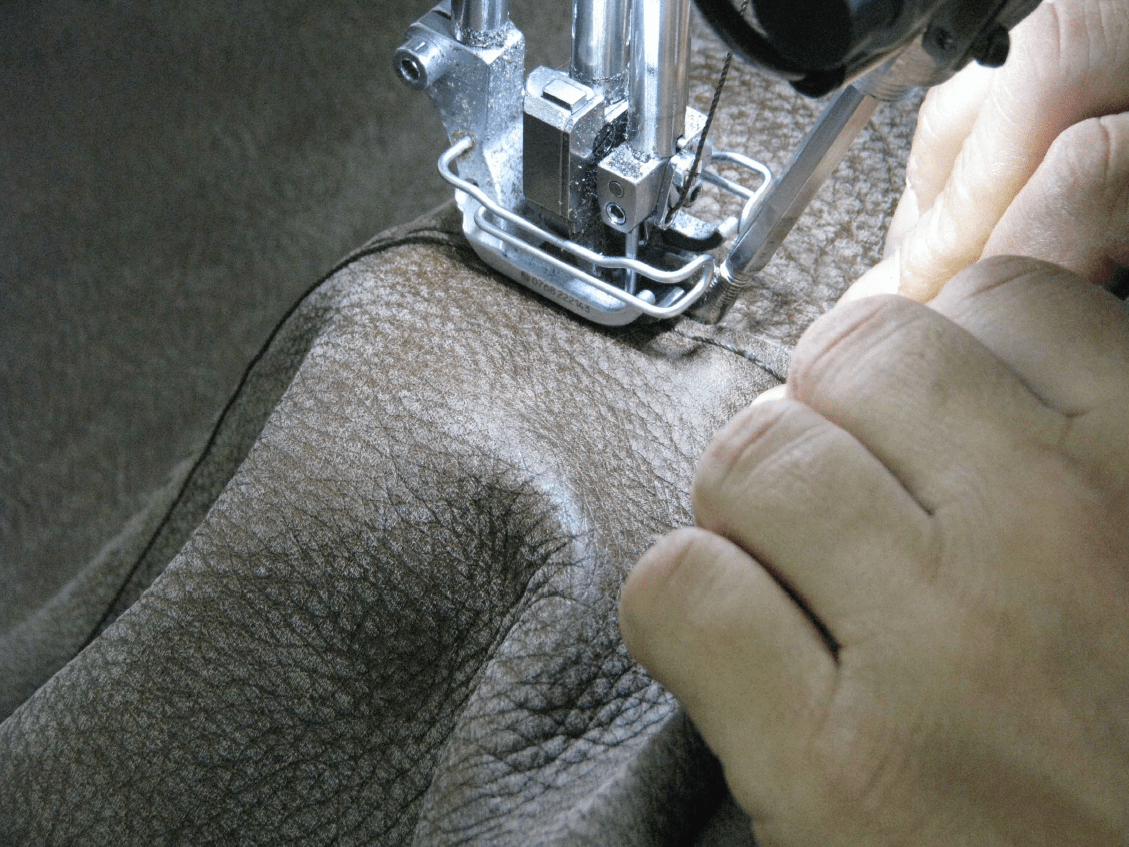

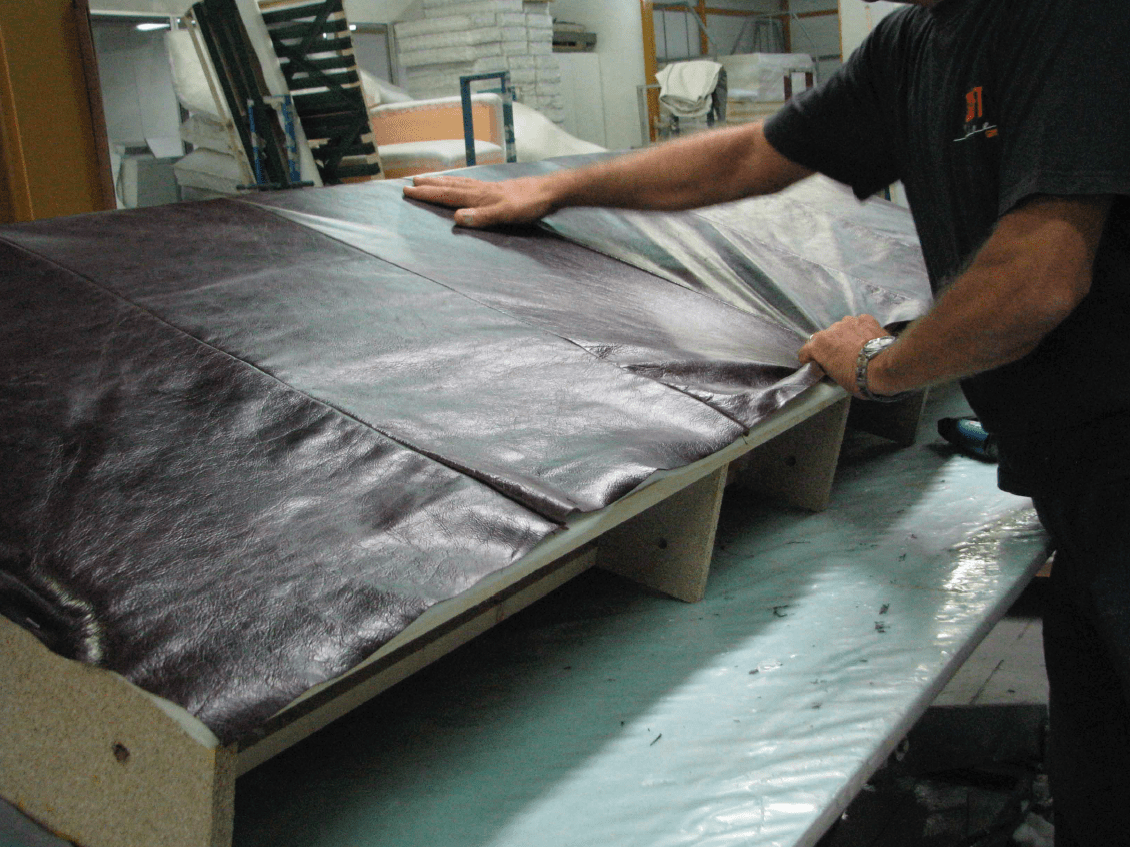

After the wood and foam components are ready for assembly, the leather is hand-cut and sewn according to the CAD patterns.

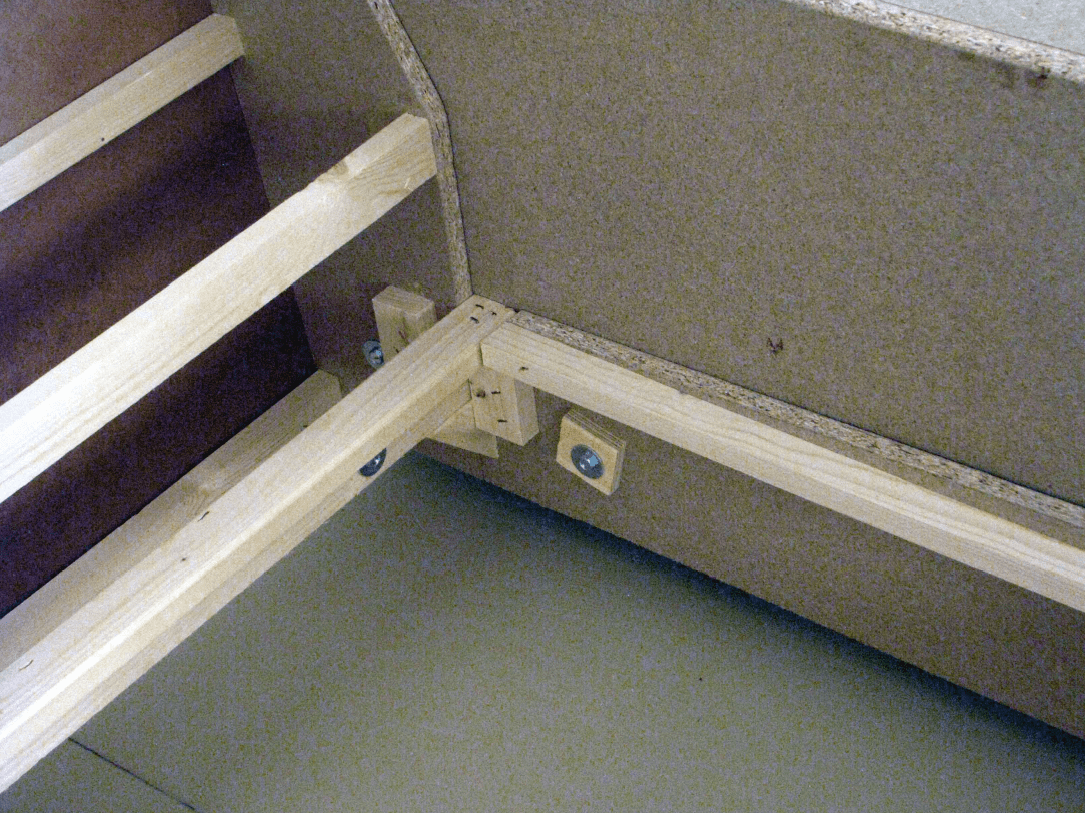

Next, the timber and plywood are joined together with nails and then stapled to create a more durable sofa frame.

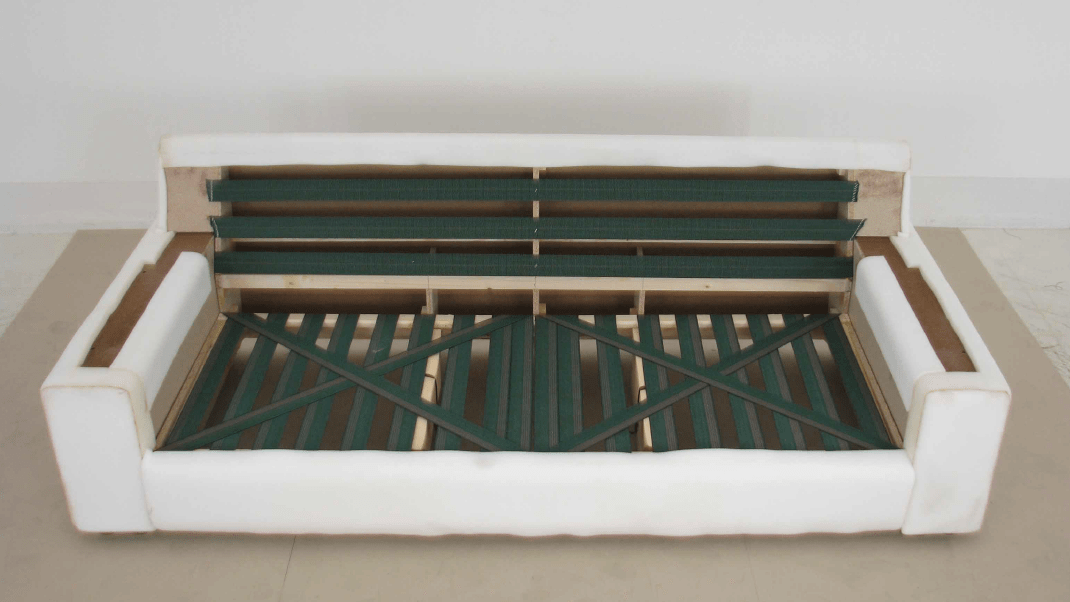

After the frame is built, elastic webbing and foam layers are used to wrap the sofa frame to give the sofa its final shape while also adding comfort.

Once the frame is wrapped in elastic webbing and foam, the sofa is ready to be upholstered. While putting the cushions and leather on the sofa frame, the upholsterer pays close attention to details to make sure that the final finished product is exactly as originally designed.

After the sofa is fully assembled, quality control inspectors carefully scrutinize the sofa to make sure that it meets Soft Line’s quality standards. Once it passes inspection, the sofa is ready to be packaged with delivery protection and then shipped.